Chicken Harvester for Sale

Quick Easy Safe Economical

Our chicken harvester machine can catch 8000-12000 broilers per hour.

Chicken Harvester for Sale

Our Chicken Harvester for Sale

Main Advantages

Our intelligent chicken harvesters have the following advantages. It is the best choice to replace the traditional manual chicken catching.

High Efficiency

Our chicken harvester has high efficiency. They can collect 8000 broilers/hour -12000 broilers/hour. The chicken weight can reach 16 tons per hour-26 tons per hour.

low injury rate

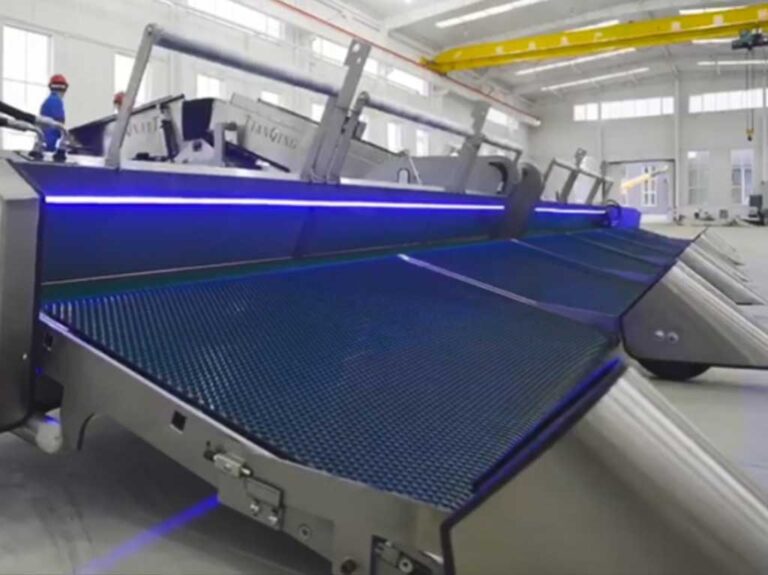

Rubber conveyor belts system guarantee chickens are well and comfortably transported with low injury rate.

Highly automated, easy to operate

Our chicken harvesters are equipped with Siemens PLC control system. It is easy to operate and has the functions of automatic walking, automatic reading, automatic weighing and automatic weighing.

Reduce labor and labor load

Instead of the manual catching. Our chicken harvester can catch broiler with much higher efficiency. The labor quantity reduced greatly.

Improve yield

Shorten the waiting time of chickens to be slaughtered, which is beneficial to reduce the number of dead chickens.

Biological safety

Avoid contact between the basket and chicken manure, which is good to biological safety.

Chicken Harvester For Sale

Quick View

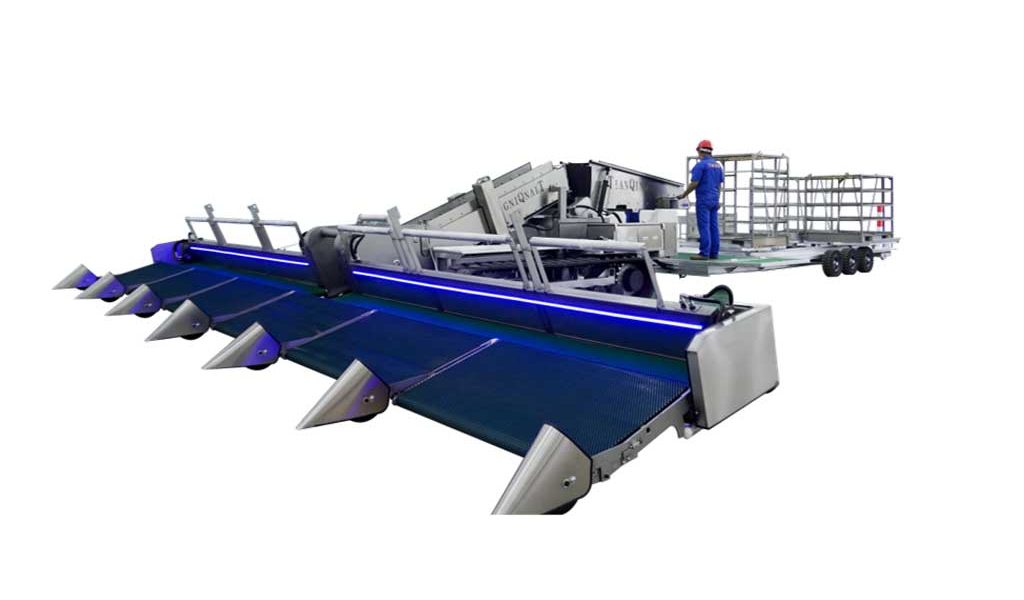

Folding harvest head

Easy for operation, transport and storage.

Harvest head can be manufactured from 3 meters to 9 meters.

Rubber Crawler Chassis

Minimize ground disturbance and minimize surface damage and leave minimal marks.

Ensure operator comfort and great noise reduction.

Full hydraulic drive

Full hydraulic drive control system, engine power source.

PLC imported from Germany Siemens or Schneider brand intelligent control system.

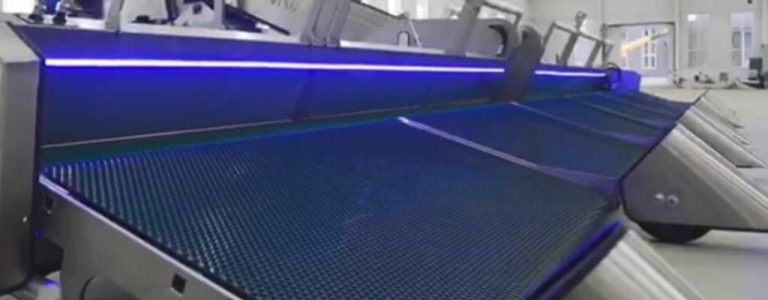

rubber belt conveying system

Low belt speed for smooth conveying.

Gentle transport is the guarantee for birds low injury rate.

Carousel

360 degree rotation can allow for a continuous loading process to the module.

Equipped with a weighing system to verify the weight of animals.

Remote Control

Remote control makes the operation become more easy, safer and more convenient.

Physical labour intensity are reduced greatly.

Classic Chicken Harvester for Sale

Our chicken harvester for sale can catch 8000-12000 broilers per hour. Our chicken harvester machine is your best solution for your chicken catching work. The two classic harvester head 6 m and 9 m. The harvester head can be customized from 3 meter to 9 meter for your chicken catching work.

6 m Chicken Harvester for Sale

Chicken Harvester 6 m model means that the harvesting width during operation is 6 meters.

9 m Chicken Harvester for Sale

Chicken Harvester 9 m model means that the harvesting width during operation is 9 meters.

Contact Us Now

We are ready to work with you now. We will give a solution for your chicken catching work with less cost and more efficiency.

Chicken Harvester For Sale

working process & instructions

Step 1 Space Preliminary Preparation

Plan the chicken catching routine according to the chicken house gate location.

Keep chickens away from the gate and make sure a 5×9 meter open space for the chicken catching machine.

After these preparation, the chicken catching machine can enter into the chicken house.

Step 2 Drive into the chicken house.

You can use remote control panel or wired control panel to drive the chicken catching machine into the chicken house.

Make sure the chicken catching machine height lower than the gate height.

Remote control panel is the normal control method. Wired control panel can be for emergency situation.

Unfold the chicken harvester head after it entered into the chicken house.

Unfold the belt No.1 and chicken separator.

Lower the chicken harvester head to the ground in the open space.

Level the tip f the chicken separator parallel to the ground.

Lock the bolt of the chicken separator.

Install the chicken harvester head tilt rod and lock it tightly.

The forklift load the steel frame full of the plastic baskets into the chicken house.

Place the steel frame on the carousel and chicken will be transported into the plastic baskets.

Step 3 Automatic Chicken Catching

Turn the knob switch of the main control panel on the chicken arm to “run belt” + “straight line gear”

Open the “belt run” rocker handle to make the belt run.

Our chicken harvesters will move forward and catch the chicken automatically.

Reverse the belt run rocker handle to stop the belt.

2 workers standing near the chicken outlet and guide the chicken into the plastic baskets.

When the plastic baskets full of chicken, workers push the basket into the steel frame.

Workers shall control the appropriate quantity of chicken into each plastic baskets.

Once the whole steel frame are fully loaded with the chicken, use the large chain joystick to changeover of the chicken baskets.

Step 4 Loading to the truck

The forklift loads the steel frame and transport steel frame to a special transport truck.

Reference Case

Chicken Harvester for Sale

CP Group use our chicken catching machine for 115,000 broilers per day. These chicken catching machines catch chicken with less cost, less time and more efficiency.

Chicken farm scale: The current daily slaughter volume is about 115,000 chickens.

Chicken catching machine: 2 sets

Four-wheel drive off-road forklifts: 5 sets

In actual use, each chicken catching machine is equipped with 2 forklifts and 1 forklift as backup.

Industry status

At present, most companies in the industry still use manpower to capture broiler chickens. The time for catching chickens is uncontrollable, resulting in a break in the slaughtering chain at slaughterhouses and also incurring high labor costs.

In view of the current situation that global livestock and poultry companies lack intelligent chicken catching machines, our company is committed to the research and development and production of intelligent chicken catching machines and related supporting equipment to fill the gap in the industry.

Our chicken catching machines are suitable for all large and medium-sized flat chicken farms. The chicken catching capacity of our chicken harvesters is 8500-11000 per hour.

Our chicken harvester has the advantage of intelligent integration, which can replace most of the labor costs. The chicken catching time is controllable. It greatly improves work efficiency, reduces labor costs, and improves corporate benefits.